- Pack

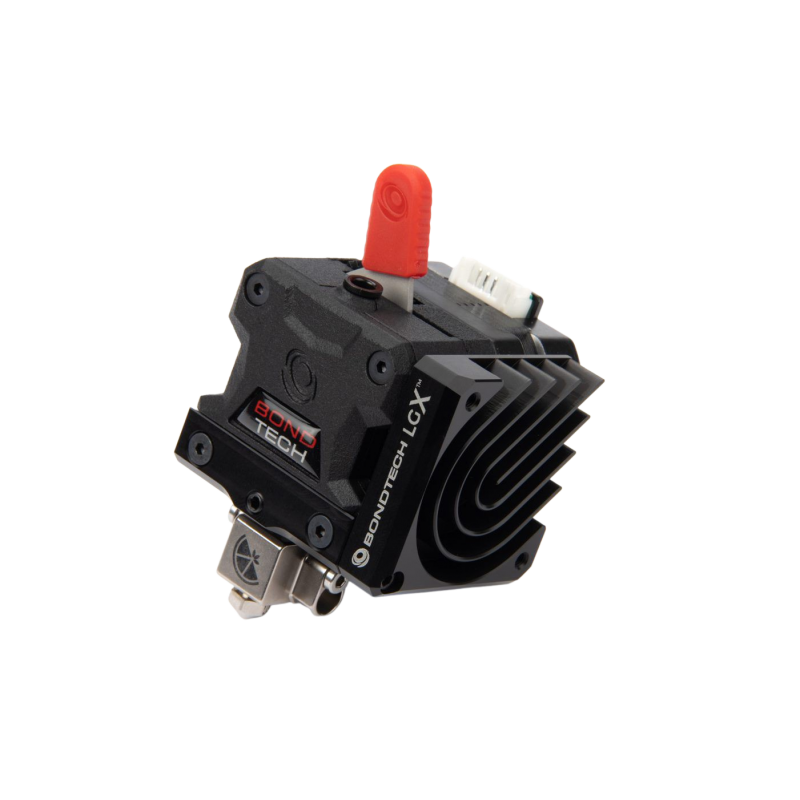

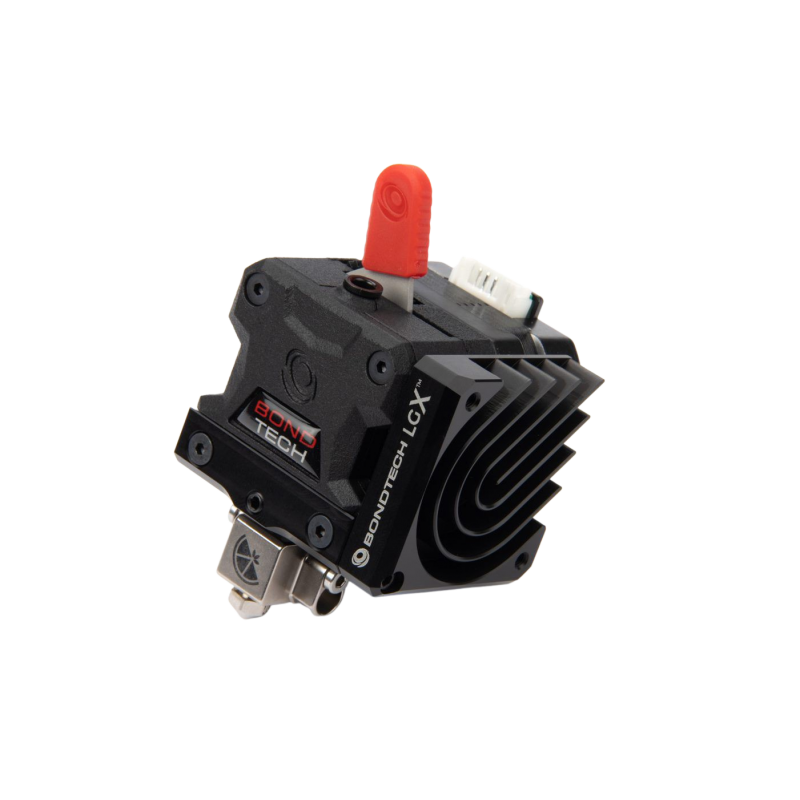

Meet the new LGX Large Gears eXtruder from Bondtech. It represents the latest innovation in dual drive technology from the company that brought you the BMG. This Print Head kit includes an LGX extruder AND the LGX For Flexibles upgrade resulting in a complete FDM print head.

Meet the new LGX Large Gears eXtruder from Bondtech. It represents the latest innovation in dual drive technology from the company that brought you the BMG. This Print Head kit includes an LGX extruder AND the LGX For Flexibles upgrade resulting in a complete FDM print head.

Master all materials

Excel with Flexibles

With the large drive wheels of the LGX™, more teeth engage the filament at the same time to increase the grip and eliminate the risk of grinding the filament. This feature, along the custom stepper motor, also prevents damages from force feeding filament to clogged or jammed hotends.

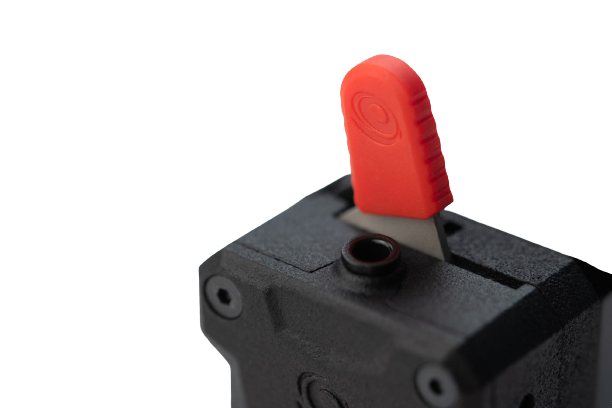

We replaced the hinge, thumbscrew and spring with a calibrated, 6 preset lever system.

The first position of the lever, all to the left, releases the engagement of the drive wheels with the filament, making filament load and unload very easy.

5 more positions, to the right, give repeatable setups to achieve repeatable results.

The whole solution is compatible with abrasive, rigid, semi-flexible, flexible and soft filaments.

From Bowden to direct drive and back… quick and easy.

Swapping hotends? Quick and easy.

The interface socket allows you to connect or swap interface plugs that serve different applications or hotends - all without opening the extruder and just 2 screws.

It is also an open door for Future Bondtech or third party plugs to expand the realm of solutions currently available.

The extruder looks amazing with the partial reveal of its drive wheels but… more than a gorgeous detail, those windows give access to easy maintenance.

The teeth can be brushed, air can be blow through and dirt can be vacuum cleaned from the outside.

No need to disassemble the extruder to keep it clean.

Compact and light.

The smallest AND the lightest, dare to compare.

Symmetric for compatibility.

No more doubts and questions about, what to choose - standard or mirrored?

Simple. There is only one!

The LGX™ is the first extruder we supply with so many mounting hole patterns.

Bottom, front, back, left and right. There are so many ways to grab it, and to mount something to it.

It is very flexible and will be easy to attach to most frame styles or carriage plates.

A small step in the right direction.

We are leaving behind the bleached & coated white boxes with color prints to start using craft cardboard and black prints made with ink based on sustainable materials only.

The Bondtech LGX™ boxes are fully recyclable.

Looking for an even deeper dive? You can find more at Bondtech Here

You might also like