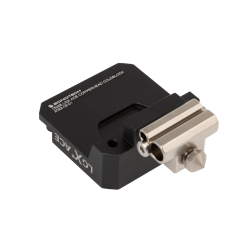

This LGX ACE Copperhead is a special short filament path hotend, co-developed by Bondtech and Slice Engineering, to be used with the LGX eXtruder.

1x LGX Black Anodized Aluminum Monolithic Cold Block and Heat Sink

1x Copperhead LGX Heat Break

1x Copperhead Hot Block

1x Bondtech M6x1x7.5 Coated Brass Nozzle 0.4mm

1x Silver Based Thermal Paste Sachet 0.5g

This LGX ACE Copperhead is a special short filament path hotend, co-developed by Bondtech and Slice Engineering, to be used with the LGX eXtruder.

It features Slice’s Copperhead bi-metallic heat-break technology and Copper hot block for improved thermal performance.

Pairing it with the LGX forms a print head that will excel at printing ALL most common materials and especially the soft and flexible.

During the long months of deep testing that preceded the launch of the LGX CHT nozzles, Bondtech discovered that shortening the post-drive filament path generates increased volumetric flow rate capacity. Similar to the LGX Shortcut Copperhead, the LGX ACE Copperhead delivers that same increase when comparing to the full Copperhead hotend.

The LGX ACE Copperhead Hotend features a monolithic air-cooled cold block and heat sink, designed and manufactured by Bondtech, that engages with the LGX extruder using its interface plug and rests at the front of the extruder. The heat sink includes the hole pattern for attaching 40×40 fans.

Our tests suggest a 4010 fan is enough to cool down the cold block and the cold zone of the heat break, due to the monolithic design of the cold block and heat sink that increases heat transmission and dissipation.

You might also like