This bi-metallic heat-break made by Slice Engineering for the Prusa Mini addresses and solves the heat-creep issues of all materials we tested.

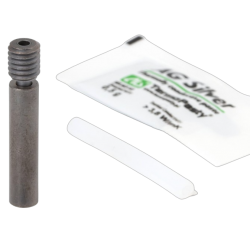

We recommend to use the included silver based thermal grease to properly fit the P Mini heat-break in the Prusa Mini’s heat-sink.

To address the heat creep issue the design features a narrower section with thinner walls. When removing the heater block or changing nozzles, caution is required.

Before removing the heater block from the heat-break (or vice versa), heat-up the nozzle, hold the heater block and release some tightening pressure from the nozzle. Let the whole group cool down. After, you can simply unscrew the heat-break from the heater block.

To remove or replace a nozzle, never forget to secure the heater block before twisting the nozzle.

You might also like