- Pack

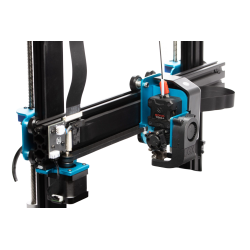

This is an LGX™ Direct Drive Setup to use on Artillery Sidewinder X1, prepared to use Mosquito™ (screw mount) hot ends from Slice Engineering. Slice Engineering Mosquito Magnum, fan, and part cooling duct included.

This is an LGX™ Direct Drive Setup to use on Artillery Sidewinder X1, prepared to use Mosquito™ (screw mount) hot ends from Slice Engineering. Slice Engineering Mosquito Magnum, fan, and part cooling duct included.

Please note that a nozzle is not included! See Bondtech's configuration of the same product for details.

This LGX™ based upgrade kit is a easy to install replacement of the stock direct drive extruder. It requires the accessories included in the LGX™ Accessories For Sidewinder X1 and Mosquito™ package.

The LGX™ is the Bondtech extruder with the highest filament grip due to its new large drive wheels that put more teeth engaging the filament.

Start using our newest extruder with our new Dual Drive Technology based on larger drive gears. This is only one of the 7 new features Bondtech implemented on an extruder.

You can read more about the new features by clicking here.

The housing parts are professionally printed with nylon for maximum strength and precision and higher temperature resistance.

You might also like