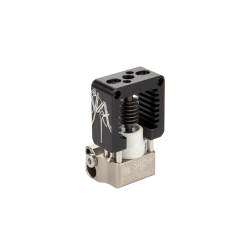

By re-imagining how a hot end is designed and structured from the ground up. The materials in each part of the Slice Engineering Mosquito Magnum have been hand selected to perform a specific task to optimize your printer’s performance with three goals in mind: lightning speed, beautiful resolution, and increased durability. The Magnum is recommended for machines needing high flow rates for fast printing, or printing with larger nozzle diameters.

Recommendation: Use on high flow applications.

(thick nozzles and thick layers)

Oh yeah, and you can change the nozzle with one hand.

Mosquito Magnum is only available for 1.75 mm filament at this time.

Slice Engineering released a brand new version of the Mosquito™ Magnum! This new versions include a revised heat break and heat sink with cool new features. The new heat break has a reinforced throat and revised radiator to prevent damage during installation or repairs. It also features the same WS2 anti-stick coating found on our line of Vanadium™ Nozzles for even better performance with PLA. The new heat sink has a wider opening for the filament path to more readily accept spliced filament from multi-material setups, like the Prusa MMU or Mosaic Palette.

The old-style heat breaks and heat sinks will not be compatible with the new ones. However, customers that desire to upgrade can retrofit their Mosquito™ to take advantage of the new features by acquiring both the heat sink and heat break together.

The Mosquito is adaptable to virtually any printer, so by swapping one component, you gain the high performance benefits of a printer worth thousands more. Since the Mosquito (designed for beauty) and Mosquito Magnum (designed for speed) are the same length, any combination of these hotends can be mounted to one carriage. So you can switch between high-flow and high-precision in the same print.

Oh yeah, and you can change the nozzle with one hand.

Are you ready to see your vision fully realized?

Whoever says “Sorry, I can’t do a GoT marathon with you on Saturday, I’m doing a big print,” clearly doesn’t have the Mosquito Magnum hotend that finishes projects 20% faster than other high flow-rate hotends on the market.

Your 3D printer can deliver the high resolution prints and take on engineering-grade plastics that other desktop printers can’t come close to. With minimal layer lines, your vision is about to become reality. Fast.

The Mosquito Magnum hotend has the same precision as our Mosquito hotend, but with a flow rate that is significantly faster.

Unlock engineering-grade plastics up to 450 °C. That means you can print car parts, medical devices, and whatever else you can dream up, and you don’t have to buy an expensive printer to do the job.

How did we accomplish this?

By reimagining how a hotend is designed and structured from the ground up. The materials in each part of the Mosquito Magnum have been hand selected to perform a specific task to optimize your printer’s performance. We went as far as using the same insulator materials that NASA uses on their space shuttle to protect the hotend’s extended melt zone.

Some might say it’s overkill.

But we say it’s necessary to create something truly excellent.

And it gives you a great anecdote for the next 3D printing convention

You might also like