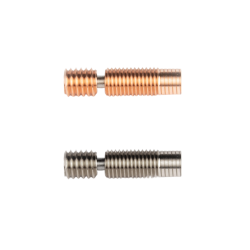

Part of the DDX phase 2 upgrade for Creality CR-10S Pro, CR-10S Pro V2, and CR-10 Max. This bi metallic heat break adapts a Slice Engineering Copperhead hot end to the factory heat sink of your Creality machine.

Part of the DDX phase 2 upgrade for Creality CR-10S Pro, CR-10S Pro V2, and CR-10 Max. This bi metallic heat break adapts a Slice Engineering Copperhead hot end to the factory heat sink of your Creality machine.

This Bimetallic Copperhead™ Heat Break is made with:

Rated up to 450 °C

Product is supplied with a W2S (Tungsten Disulfide) plated Stainless Steel and Copper Heat break. Some images attached may show the un-plated Copper Heat Break.

The Copperhead™ is a low-cost, open-source hotend option that can handle the heat — heat creep, that is. Replace your factory model hotend with the Copperhead™, to upgrade your 3D printer’s performance and reduce jamming, giving you a smooth print every time.

Unlike most materials, plastics don’t have a clean transition from solid to liquid during melting. As filament moves through the hotend, it heats up and reaches the material’s glass transition temperature (Tg), entering a semi-solid, semi-liquid, “gooey” state. While in this state, the plastic responds to applied forces like a wet noodle, causing undesirable print effects like reduction in resolution, blobbing and jamming. An efficient heat break narrows the physical distance during which the plastic is at it’s Tg, and thus improves 3D printer performance. The Bimetallic Heat Break™ from Slice Engineering® is the only heat break designed through the use of thermal imaging to optimize heat transfer.

You might also like